WSL:

Whole Skin Locomotion

Researchers: Eric Williams

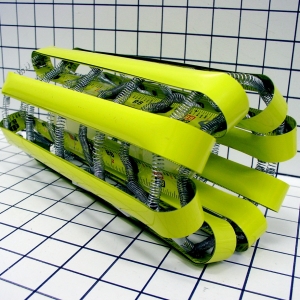

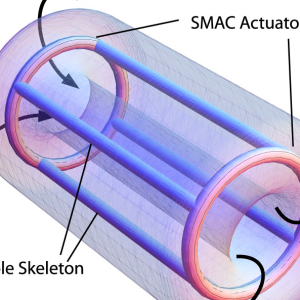

The whole skin locomotion (WSL) concept relies on the actuation of the outer skin to attain mobility in collapsed environments as the interior of the robot moves and the exterior is stationary.

The eversion of the the outer skin is accomplished by the actuation of the shape memory alloy composite actuators (SMAC). The SMAC actuators are comprised of silicone rubber cast around equally spaced SMA wires. The undeformed actuators are in the shape of hollow circular cylindrical shells. Upon deformation, the actuators use the Shape Memory Effect of the SMA wires to create the eversion motion.

Upon bending the undeformed SMAC, strains are introduced that are then recovered through the Shape Memory Effect. The control of individual wires embedded into the SMAC allows for control over the thrust force of the actuators. This force causes the outer skin to evert through the SMAC.Another mechanism that is under investigation is the actuation of rings on the outer surface of the WSL robot. The actuation of individual rings generates a non symmetric shape in the outer shell that causes thrust force in the direction of motion. A Finite Element Analysis was conducted to determine the effects of ring forces on the shell. For this analysis 3D shell elements were developed and the results have provided insight into the mechanics of this form of actuation.

-

Development of a Shape Memory Alloy Composite for the Whole Skin Locomotion Robot, Smart Materials, Adaptive Structures and Intelligent Systems, Oxnard CA 2008 .

-

Mechanics of the Whole Skin Locomotion Mechanism Using the Concentric Solid Tube Model: How the Geometry and Friction Affect Its Efficiency and Force Transmission Characteristics, ASME Journal of Mechanisms and Robotics, 2008.